Brief Introduction

The purpose of pre-expansion is to produce expandable polystyrene particles of the desired density. During pre-expansion, the EPS resins are fed to a vessel containing an agitator and controlled steam and air supplies, this vessel is called EPS Pre-expander, or EPS Batch Pre-expander Machine. The diameter of the particles increases while the density of the resin decreases. After exiting from the EPS pre-expander, the expanded beads will flow through a dryer to remove moisture, and then go to aging silo.

Body of EPS Batch Pre-expander

• Expansion chamber is made of SUS 304 stainless steel, cylindrical shape inside & square shape outside, with insulation layer.

• Agitator is made of SUS 304 stainless steel, speed is adjustable by frequency converter during different steaming stage.

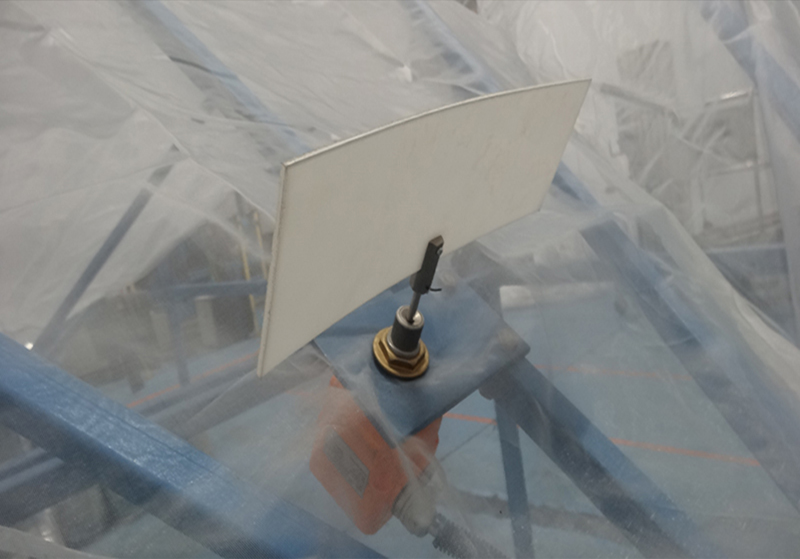

• Discharge door located on the side of the vessel, to empty the chamber fast.

• Safety fence to top & around stairs.

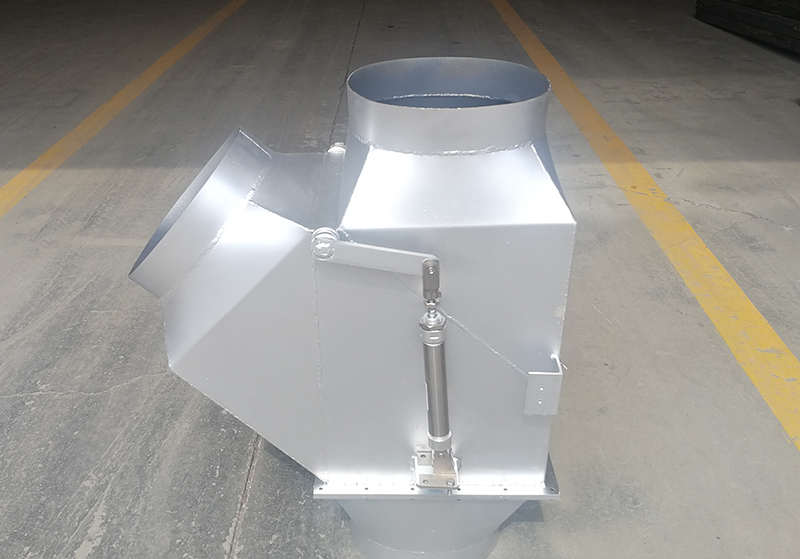

Screw Loading system

A screw loading machine with a tank ( approx. 1.5 m3 volume , 1200kg EPS beads) is using to load EPS resin to Dosing unit. And then filling to the expansion chamber by gravity.

Fluid bed dryer

On top, there is waste steam collection cover, inside floor parts made of SUS 304 stainless steel, The dryer is equipped with a steam-air heat exchanger inside, which avoid the beads from thermal shock. At the end of dryer, there is a rotary system to send EPS beads to specified silos.

2nd Expansion Unit

2nd expansion system is available for this EPS pre-expander to get lower density. The PLC control the 2nd expansion in a fixed volume. The filling from the silo to the machine is done by a vacuum fan.

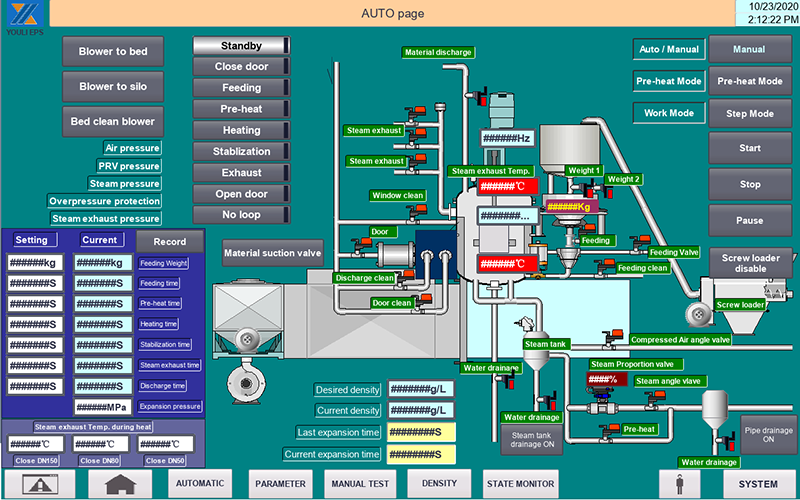

Control Panel

Main cabinet,with security lock,is equipped with Delta/Siemens touch screen and PLC.

All parameters and recipes can be added, revised and saved in PLC.

Density weighting & print Unit

After each cycle, the density weighting system will suck a fixed volume material from the dryer and weighed. The density data can be saved in PLC or printed on a paper.

Production capacity

• Model: EPS Batch Pre-expander, Model: SPJY1600G

• Chamber diameter: 1600mm,

• Chamber height: 2500mm,

• Tolerance: ±1.5%

• Output: 1600~1800Kg/h, @ density 15kg/m3

• Model: EPS Pre-expander Machine, Model: SPJY2000G

• Chamber diameter: 2000mm,

• Chamber height: 2000mm,

• Tolerance: ±1.5%

• Output: 2000~2200Kg/h, @ density 15kg/m3

Features

• CE certificate

• Multiple safety features.

• Pressure Reduction Valve from Japan is used for steam control

• PID System ensure accuracy for EPS pre-expansion.

• Equipped with “Mettler Toledo”weighting sensor to increase weight accuracy

• Two vibration level sensor detect material level

• Equipped with waste heat collection and reuse system

• Frequency control of motor speed during expansion

• Fluid bed is equipped with heater to shorten aging time

• Second expansion is available for lower density

• Body: RAL5012 Blue + RAL7035 Grey

• Automatic density weighting & printer system is optional

• Automatic EPS Silo System is available to work with EPS Pre-expander together.

Main parts

• Touch Screen & PLC: Siemens/Germany

• Temperature sensor: Siemens/Germany

• Pressure sensor: Siemens/Germany

• Electronics: Schneider/France

• Vibration level sensor: Jiwei/China

• Agitator motor: SEW/Germany

• Butterfly valve:Flowx/Italy

• Angle valve: ESG/China

• Weight sensor: Mettler Toledo/Switherland

• Pressure Reduction valve: Yoshitake/Japan

• Pneumatic parts: SMC/Japan

• Photo sensor: Autonics/Korea

EPS Automatic silo system

The silos are controlled by PLC & Touch Screen, level sensors and pneumatic valve. Silo body made of square steel pipe and nylon net(anti-statics); Galvanized pipe used for EPS transportation, each silo equipped with one inlet pipe (DN200 or 250) and one outlet pipe (DN200 or 250).

While one silo is full during feeding, the system would stop feed this silo and automatically switch to feed another silo. While one silo is empty during discharge, the system would stop suck this silo and automatically switch to suck another silo.

It works with EPS Pre-expander to increase plant automation & keeps the plant clean.