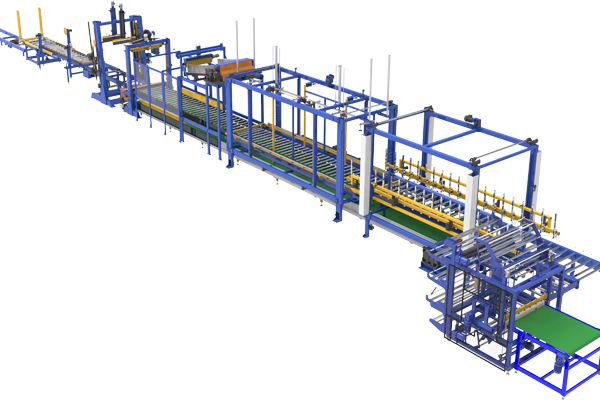

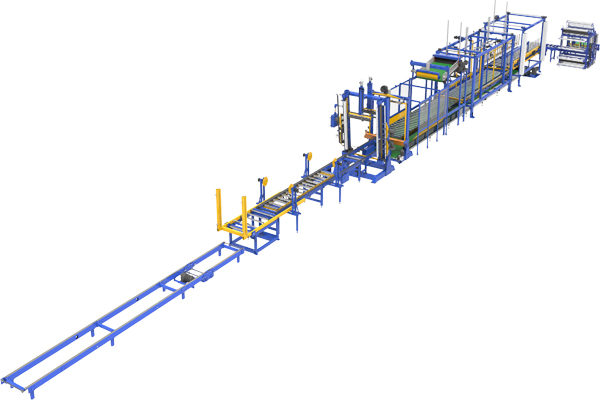

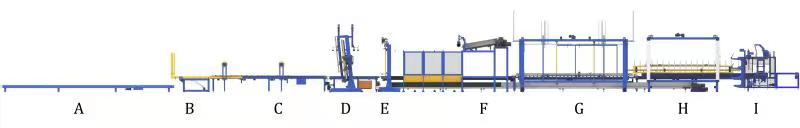

EPS Cutting Line

A. EPS block storage line

6 blocks can be stored on the line. The blocks are positioned by operator using the forklift.

When the tilter is free, the block will move to tilter unit for start cutting stage automatically.

B. EPS Block Tilting Unit

The tilter is driven by hydraulic. When block is tilter completely, the unit lays the block down on the horizontal cutting chain conveyor and move forwards.

C. Horizontal cut block alignment

When EPS block arrive at the specific sensor, a air cylinder would life the EPS block and 4 pusher will align the EPS block in proper cutting position, to keep cutting precision.

D. Horizontal cut

Automatic wire setting system (Patent Design) & oscillation cut are equipped in this part. The wires set very fast to desired thickness. 60 wires can settled with 3 minutes, thickness tolerance ±0.5mm. Four fans on two sides for wire end cooling and one fan on bottom.

E. Vertical cut

Oscillation cut is equipped in this part. one fan on top & one fan on bottom to cool wire ends.

Automatic wire setting is optional.

F. Top Scrap Removal & Pre-crusher

Equipped with vacuum suction unit, the top scrap during cutting would be sucked to a transportation belt and taken to the pre-crusher. Afterwards the pre-crushed material transferred through a fan to the recycling system.

G. Cross cut & block alignment

The block can be cut in different length in this unit. When block goes into this stage completely, the alignment system would align the EPS block into proper cutting position to keep cutting precision. The wire moves from bottom to top. Automatic wire setting & oscillation cut is optional.

H. Automatic De-stacking Unit & side scrap Pre-crusher

After the cross cutting, the packs come on the final motorized conveyor and prepared to enter the de-stacker. The De-stacker would life the upper part of EPS block first, and down part EPS will go to packing machine first. After all bottom blocks are packed, the upper part of EPS falling down to the conveyor and go for packing.

Side scrap & bottom scrap pre-crusher is equipped in this stage. The scraps are collected by a transportation belt to the pre-crusher. Afterwards the pre-crushed material transferred through a fan to the recycling system.

EPS Block Packing Machine

The EPS Packing Machine use PE film to wrap the EPS packs from 4 sides. Special design to keep the package durable. Packing speed is fast and no need to heat the film by oven. For more details please find it in EPS wrapping machine pages.

Production capacity

Model: SPQ(2000/3000/4000/5000/6000)B

• Suitable for EPS block length: 2000-6000mm

• Suitable for EPS block Width: 1200mm

• Suitable for EPS block Thickness: 1200mm

• Cutting Speed: 1.8~2m/min @ density 15kg/m3

Features

• CE Certificate

• Multiple safety features

• High output with high automation

• Automatic wire setting in Horizontal cut, vertical and cross cut is optional

• Oscillation cut in horizontal vertical cut and cross cut is optional

• Wire ends cooling

• Top, side and bottom scrap is available

• Wire break warning system is optional

• The machine can be customized based on end-user’s special request

• Machine color: Mould body RAL5012 Blue + RAL1021 Yellow